הכרם והיקב

תל גזר – תחייתה של תעשיית היין

גזר, ישוב שנוסד באלף הרביעי לפני הספירה, ממוקם ממש במרכז הארץ על דרך המלך ממצרים צפונה ושולט על כל מישור החוף. בימים יפים, אפשר לראות ממרום תל גזר את אשדוד ואשקלון בדרום, את תל אביב וגוש דן בצפון. העומד על התל יכול היה לראות כל ספינה שמגיעה ליפו, כל שיירה שעולה לירושלים וכל תנועה בסביבות מעיינות הירקון, ליד ראש העין.

אזור גזר ידוע כאזור גידול גפנים מזה מאות שנים. כבר בתקופת המקרא ישנן עדויות לגידול ענבים שהיוו את הבסיס לתעשיית היין האיכותי סביב תל גזר מתקופת מלכות שלמה ועד היום. בסיור בסביבת תל גזר ניתן למצוא עדויות ליקבים וגתות שיועדו לעשיית יין בימי קדם. רבים מהם נחפרו ונחשפו וניתן לראותם גם היום. בעקבות פריחת יקבי הבוטיק והכרמים, ועם תחייתה של תעשיית שמן הזית בארץ, חוזר האזור לגדולתו וצובר תאוצה.

כפר בן נון בעמק איילון, השייך למועצה האזורית גזר, הוקם בשנת 1952 ונמצא באזור עשיר בהיסטוריה יהודית בת למעלה מ 1000 שנה לפני הספירה. הכניסה המקורית לכפר הייתה דרך רומאית עתיקה, שחיברה בין דרך המלך באזור הרי ירושלים לכביש לדרך הים. דרך זו עברה בסמוך לגבעה הסמוכה ליקב בן-נון, שם התגלו שתי גתות יין עתיקות.

אחת הגתות זוהתה ע”י מומחים כגת מסוג משטח דריכת ענבים מתקופת בית ראשון (960 לפנה”ס). הגת השניה, הנה מאוחרת יותר, משוערכת לתקופת בית שני (כ -500 לפני הספירה) את הנה חריגה בגודלה וככל הנראה היתה ה”מפעל” המקומי מסוג מכבש קורה. במרחק קצר מהגתות העתיקות נמצא מקווה טהרה, המוערך למתקופת החשמונאים (140 לפנה”ס – 63 לפנה”ס) ומהווה עדות מובהקת לקיום ישוב יהודי שעסק בעשיית יין, לפני למעלה מ 2000 שנה, בדיוק במקום בו נמצא כיום יקב בן נון.

הטרואר – Vineyard-Terroir

האזור מאופיין במיקרו אקלים ייחודי הכולל משפך קור לעמק עם רוח קרה בלילה גם בתקופת הקיץ. האוויר מהרי ירושלים מעניק את היובש הנדרש לכרם. מיקרו אקלים ייחודי זה משביח את הבשלת הענבים ומאפשר מיצוי המינרלים מקרקע הכרם וצבירת חומרי הטעם והארומה בעינב.

הכרם ניטע באדמות כפר בן נון, שבעמק איילון, בשיפולי הרי יהודה בואך ירושלים בין הישובים כרמי יוסף לכפר בן נון, במקום בו היו כרמים רבים בעבר. הכרם גדל באדמה כבדה עמוסת גיר המהווה בסיס מצוין לחומרי הטעם המתרכזים בעינב. שיפוע הקרקע יוצר ניקוז מצוין אשר מונע עודפי מים מלהצטבר.

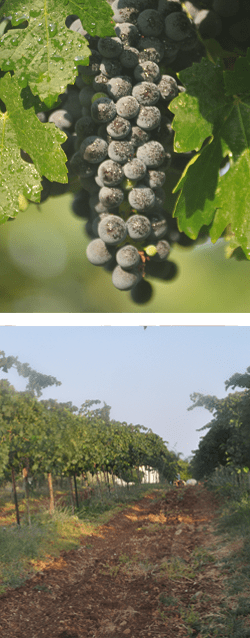

הכרם והטיפול בענבים

תנאי גידול מבוקרים וזמירה נאותה מאפשרים יחס מתאים בין כמות הנוף לכמות הפרי, יחס זה מבטיח תנאי הבשלה אופטימליים של האשכול. הודות להשקיה מדויקת, עקת יובש וחשיפה מבוקרת לקרינת השמש , מתפתחים ענבים איכותיים בעלי גרגר קטן עם ריכוז גבוה של חומרי טעם.

אנחנו מקפידים על כמות אשכולות ענבים מדודה לכל גפן, כדי לוודא שכל עינב מקבל מהגפן ומהקרקע את מירב המינרלים וחומרי הטעם הנדרשים לייצור יין איכותי ומשובח. אנחנו משתדלים לדלל את היבול ולהגבילו ל 800 ק”ג לדונם,כדי לאפשר לגפן לרכז באשכולות שנותרו את חומרי הטעם, הצבע והארומה. בכרם כיום גדלים זני מרלו קברנה סוביניון. חומר הריבוי לשתילים הובא בהזמנה מיוחדת מצרפת. השתילה התבצעה במו ידנו, כשאנו מקפידים להעניק תשומת לב אישית לכל שתיל. כבר בשנים הראשונות הכרם הניב ענבים בעלי איכות ארומה וטעם יוצאי דופן. ב 2016 הרחבנו את הכרם עם זני מלבק ,פטי ורדו וסאן ג’ובזה להרחבת מגוון היינות.

תהליך הייצור

כבר לפני אלפי שנים בני אדם ייצרו יין בהצלחה, אך כדי לייצר יין איכותי, נדרשת מקצוענות , סביבה מתאימה וכמובן ענבים איכותיים. אנחנו ביקב בן נון מאמינים כי על מנת להשיג יין איכותי יש להשקיע, לטפח ובעיקר לאהוב את כל אחד משלבי ייצור היין השונים – משלב הכרם ועד בקבוק היין.

תהליך ייצור היין ביקב מתחיל ביום הבציר, שהינו יום חג בכרם וביקב. כל היין שלנו הינו תוצר של בציר ידני המתבצע בסיוע חברים ובני המשפחה עם עלות השחר. כל חלקה נבצרת בנפרד ובהגעת הענבים אל היקב הנמצא לצד הכרם, הענבים מקוררים למשך יום אחד בטמפרטורה של כ- 4-6 מעלות כדי שניתן יהיה להתחיל את תהליך ייצור היין בטמפרטורה אחידה ומבוקרת. בבוקר המעיכה, אנחנו ממיינים את הענבים, בעבודה ידנית קפדנית ומעבירים את האשכולות המובחרים אל המפריד מועך הלא הוא ה”קרשר”, המפריד בין הענבים לשזרות (גבעולים) ומבקע בעדינות את הענבים בדיוק במידה הנדרשת כדי להכינם לתהליך התסיסה במכלים.

אנו מבצעים את התסיסה במכלי נירוסטה מקוררים כדי לשמור ולנהל את תהליך התסיסה בקצב המתאים לכל זן, מידת ההבשלה וסוג היין המתוכנן. במטרה להביא למיצוי צבע וחומרי טעם מהקליפות. התסיסה במכלים אורכת בין 7-14 ימים ומסתיימת כשכל הסוכר שבענבים הפך לאלכוהול. במהלך התסיסה, אנו שואבים כל כמה שעות בעדינות את המיץ מתחתית המכל ושופכים אותו בעדינות על קליפת הענבים שהצטברו בראשו, כדי לגרום לקליפות בחלקו העליון שלהמיכל לשקוע אל הנוזל למיצוי הטעם והצבע.

בתום התסיסה הכוהלית מכניסים את הנוזל מהמכלים למכבש, ממנו זורם יין ללא קליפות וגרעינים אל מכלי התסיסה החיידקית. יום העבודה עם המכבש (יום ה – PRESS) הינו עוד אחד מימי השמחה הגדולים ביקב בו היין הצעיר נשפך לראשונה כשהוא ללא קליפות וגרעינים. ביום זה היינן בודק ומעריך איכותית את עמלם של הכורמים בשנה הקודמת. לאחר הכבישה, היין ממשיך בתהליך תסיסה איטית ללא חמצן (תסיסה חיידקית). תהליך זה מתבצע בטמפרטורה קרה ומבוקרת לשם מיצוי פוטנציאל איכות העינב. בתום התסיסה החיידקית, תבוצע שפייה של היין והעברתו להתבגרות והתיישנות בחביות עץ אלון.

אנו מיישנים את היין בחביות עץ אלון צרפתיות. בחביות היין עובר תהליך מיקרו חמצון איטי דרך דפנות החבית, ליין נוספים טעמי העץ האופייניים, המתווספים אל טעמי הפרי מן הכרם. אנו מיישנים את היין בחביות למשך שנה עד שנתיים, תלוי בסוג היין אותו אנו מייצרים.

בתום תהליך היישון, מתחיל השלב האחרון של ייצור היין ליצירת יין מאוזן ועשיר בטעמים. בטעימות חוזרות ונשנות, היינן בוחר מכלל החביות ומכל סוגי היין, את תמהיל ערוב הטעמים המיטבי – ה”בלנד”. התמהיל שנבחר מיוצר ומועבר למכלי הנירוסטה להצללה וייצוב עד לבקבוק. לאחר שהתייצב והוצלל מועבר היין לבקבוק.

התהליך מסתיים בפיקוק בפקק שעם איכותי, חיתום הפקק בקפסולה והדבקת תווית לבקבוק. הבקבוק שיוצר זה עתה, מושכב כעת למספר חודשים בתנאי קור וחושך אופטימליים כדי לתת ליין להירגע בטרם הוצאתו לשיווק.